CASTROL

enough for high-performance CPUs and GPUs required by AI.”

As processing power increases, what was once sufficient is now becoming a bottleneck for technology advancement.

“What we offer is not just a fluid, but also the service, maintenance and refill as part of our complete solution”

Nick Barrett, Senior Engineer – Data Centre Testing at Castrol, points to the ongoing evolution of processing hardware: “All of those changes going on in the industry lead to higher-powered chips. We can do more work, but that means more heat generation.”

Using automotive expertise to drive data centre innovation Castrol’s entry into the data centre cooling market builds upon its extensive thermal management experience in the automotive sector, particularly with electric vehicles (EVs). Now, the company is on a pathway of change, exploring opportunities to provide solutions and services that will complement its core lubricants business and provide more value to customers.

SUNG KIM ,HEAD OF DATA CENTRE LIQUID COOLING SOLUTIONS, CASTROL

Chris emphasises that this transition still aligns with Castrol’s traditional business approach: “It’s basically an extension of what we’ve always done, fluid interaction with an application. It’s now about understanding how our fluids can improve the performance of data centres.”

When it comes to data centres, Castrol is using dielectric fluids, using its experience with EV cooling systems to inform its approach to data centre cooling solutions. This has enabled Castrol to leverage its existing expertise in a new market.

The company’s approach to data centre cooling reflects its broader business strategy, understanding data centre operators’ need for reliable, end-to-end mission-critical solutions.

“We’ve been working with dielectric fluids for a long time,” Chris explains. “Our first EV fluid approval was back in 2013. Now we’ve got hundreds of EV fluid approvals around the world. Some of those EV fluids are immersion, dielectric fluids that we’re working on with EV OEMs in terms of immersion cooling their batteries.”

Sung adds: “In terms of liquid cooling solutions from Castrol, what we offer is not just a fluid, but also the service, maintenance and refill as part of our complete solution.

184

July 2025CREDIT : XXX

CASTROL

Sung Kim, Global Head of Data Centre

Liquid Cooling Solutions, Castrol

CASTROL

“We have this opportunity of joint development and co-engineering with the customers, so not just developing our own fluid, but working closely with customers to understand their pain points.”

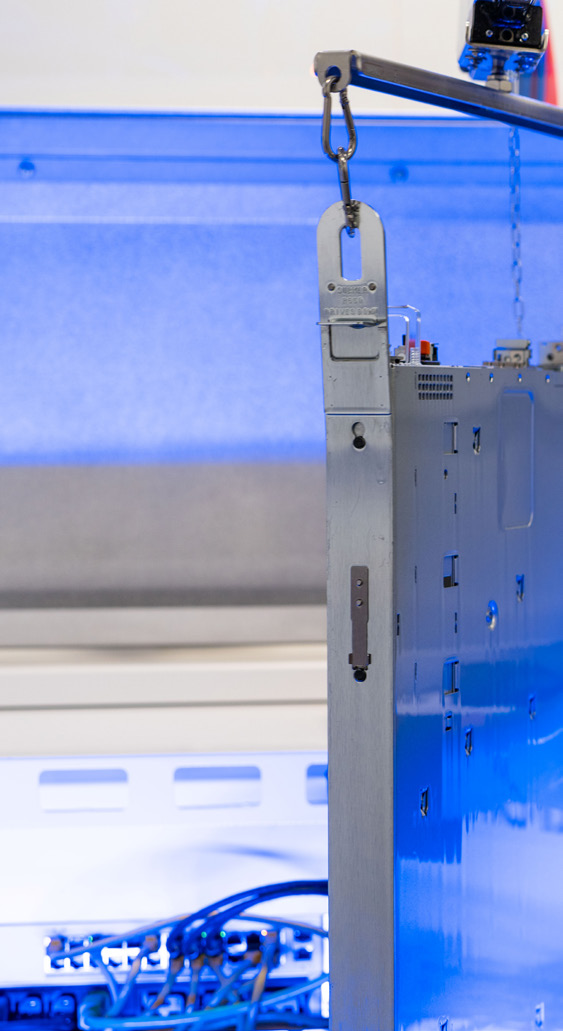

Powering the ecosystem with collaboration When speaking with the Castrol team on site in Pangbourne in the UK, a recurring theme is the importance placed on the company’s partnerships. With immersion cooling changing how data centre hardware is deployed and managed, collaboration across multiple stakeholders is essential for success.

“Once you start moving into things like direct chip and immersion, you have fluid coming very close to the IT,” Stephen explains. “All the different components are going to be touched by the fluid – the tank, the pump, the CDU, the piping, the wires, the servers, the chips.

IMMERSION COOLING :

“This means all of the different industry components need to be comfortable with the idea of moving over. If one party is saying they’re not quite ready for that transition, that’s holding back the whole thing.”

energy saving

Stephen elaborates on the ecosystem relationships that Castrol has cultivated: “From an immersion perspective, we have very good relationships with the technology environment. We work a lot with all the different chip companies, the cooling system manufacturers, server OEMs and many different component manufacturers.”

water consumption reduction

(Source: Castrol)186

July 2025

CASTROL